| Method: melting, stirring, mixing and homogenization |

| Applications: geological samples, cements, minerals, slags, ceramics, oxides, glasses, metals, ferro-alloys, sulfides, fluorides, alloys, etc. |

| Produces: vitreous X-ray discs / peroxide or pyrosulfate solutions / samples for AA and ICP |

| Programs: 50 independent editable programs |

| Maximum consumption: 1500 W |

| Power supply: 220 V - 15 A |

| Control: PC |

| Cooling: closed circuit with 300 W chiller / open circuit through external power 1.5 LPM |

| Working frequency: 130..160 KHz |

| Elements |

| programmable: crucible stirring system / crucible stirring angle / dump speed and angle / solution revolution system / ventilation mold and crucible cooling system |

| Control |

| temperature: 400 to 1200ºC limited by software |

| Software: graphical and intuitive. Diagnosis and parameterization |

| Accessories: platinum and zirconium crucibles and platinum molds |

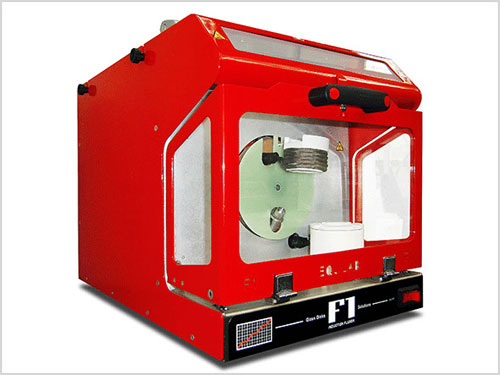

| Dimensions: 42 cm (height) x 35.5 cm (width) x 50 cm (depth) |

| Approximate weight: 20 kg |